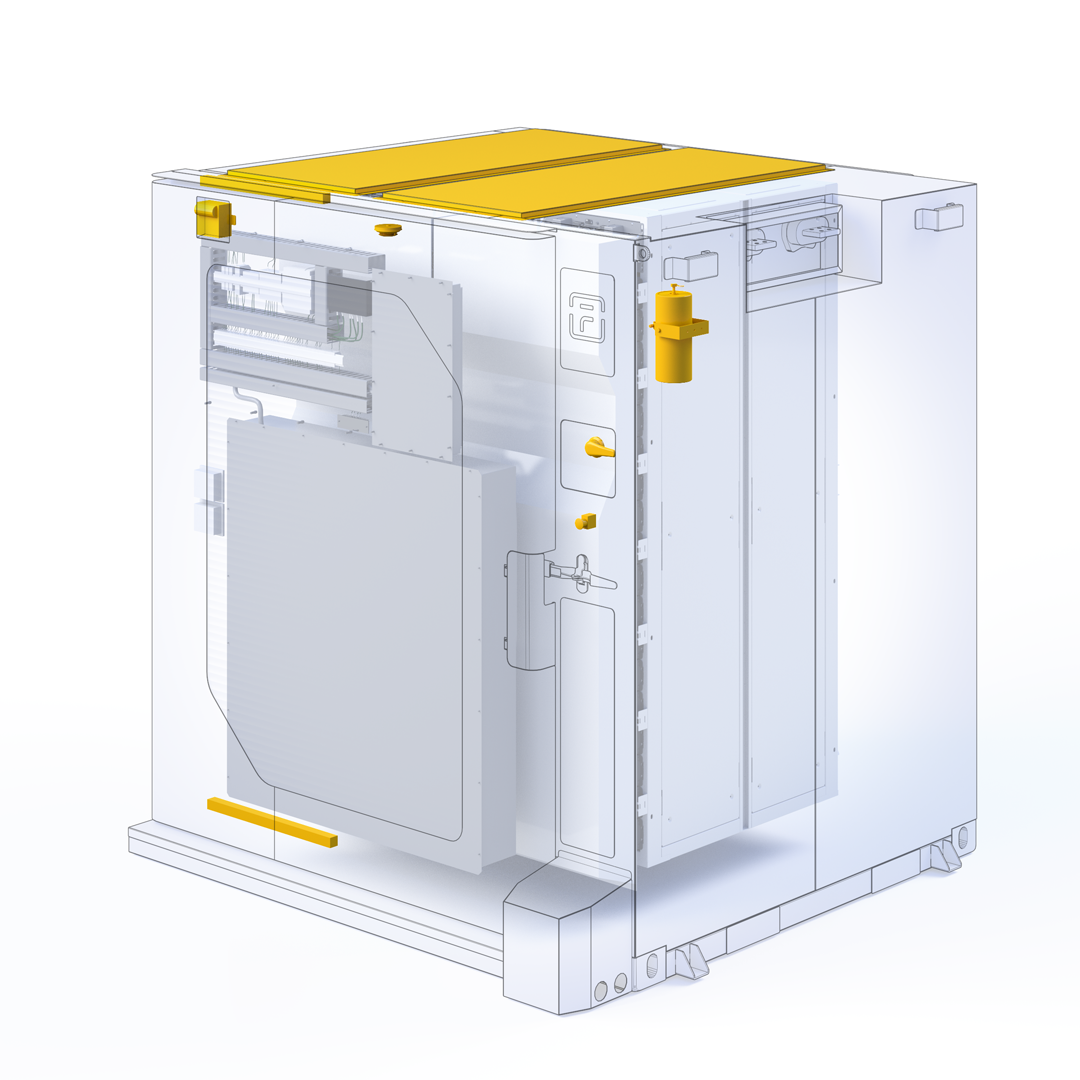

With more than a decade of experience deploying and operating energy storage systems for our customers, the Fluence fleet has delivered grid services with a strong safety record around the globe.

We see safety as a foundational element of our corporate value of Responsibility — rooted in our heritage of power generation and industrial systems design. Safety is all-pervasive in our company culture and the partnerships we build with our customers, from system design to construction and operations.